|

Ford made four different cylinder head and intake manifold setups for the 427.

These are the low riser, medium riser, high riser, and tunnel port. "Riser" in this

context refers to the height of the intake manifold above the head. The higher, the

more direct the path from carburetor to intake valve.

The first 427 head was the low riser. These were a holdover from the 406.

Intake ports measured 2.34" x 1.34".

These featured 2.04" intake valves and 1.66" exhaust valves. In March 1963 the intake

valves are enlarged to 2.09". Then for 1964 a minor modification was made just below the

intake valve seat. A venturi like ring was added to improve flow. This was then used on

all subsequent FE heads. This basic casting with revised exhaust port bolt patterns and

Thermactor provisions was later used for the 428 CJ.

Developed next was the high riser. Very tall 2.72" x 1.34" intake ports and a matching

intake manifold placed the carburetor high up above the ports with a clear shot to the valves.

This combination was the reason for the teardrop hood bubbles found on Thunderbolt Fairlanes

and lightweight Galaxies. Exhaust ports were slightly larger at 1.86" x 1.30". Intake and

exhaust valves sizes were up, too, at 2.19" and 1.73" respectively. The valves were made

of special alloy to be very light, and had tulip shaped heads in an effort to improve flow.

The combustion chambers were fully machined.

NASCAR outlawed the bubble hoods. This lead the engineers back to the drawing boards resulting

in heads. In 1965 the medium riser was released. This had much smaller intake ports,

2.06" x 1.38" but with better internal design that flows almost as well as the high riser. The

valves are are the same as the high riser but are spaced farther apart in the chamber to accomodate the altered

path of the intake ports. Slightly different valve train components are required. The medium

riser is the best head for all around high performance use.

|

|

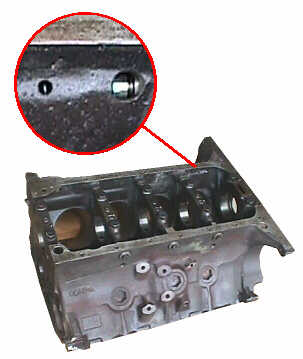

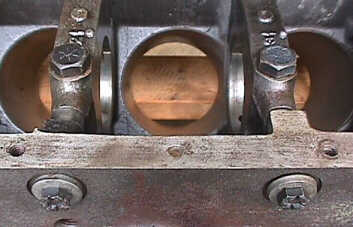

The last of the heads is the tunnel port, so called because the pushrod runs through a tube,

or tunnel, passing right through the middle of the enormous intake port. The ports were

nearly round, measuring 2.17" x 2.34". The intake valves were again made larger, 2.25".

This same idea was tried for Trans Am racing in 1968 with the

Tunnel Port 302.

Quite a bit different from the restrictor plate engines running in NASCAR today.

|

|