|

"Actually, we began our inquest with extensive rework

of the existing 271 hp heads.", said Dan Gurney holding back a smile.

"At the peak of our testing with the 271 hp cast iron heads on a 325-inch block, we were pulling as much as 448 hp on gasoline. It was about this time we figured a few improvements along the lines of a new head design might give us even more power, so we got after it." |

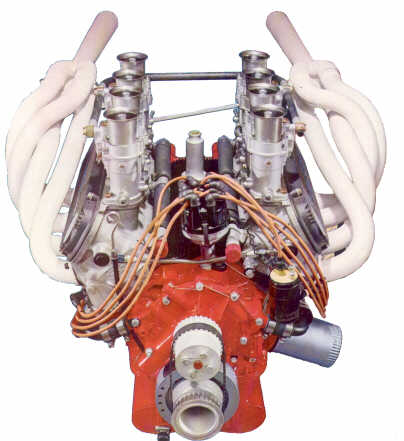

| The new heads, cast of aluminum alloy by Alcoa, did evolve. The intake ports were a short shot, leading directly from the carburetors and aimed straight at the combustion chamber. No intake manifold is used. The Webers bolt directly to the cylinder heads. Steel valve seats were used on the 2-1/32" intakes, and bronze on the 1-5/8" exhaust. Normal 45 degree seat angles were used. Rockers are shaft mounted with removable stands. Three different heads designs were developed, including one to fit under the stock hood of a Mustang. | |

|

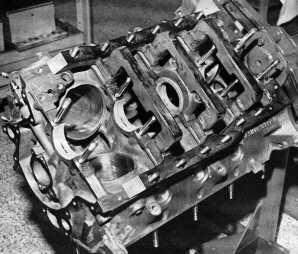

Not much remains of the stock 289 HP bottom end. The crankshafts were custom made by Dearborn Crankshaft Company. Bearing inserts were taken from the Ford DOHC Indy engine. Carrillo rods, super finished and shot peened were fitted. Stock 289 oil pans were chopped up and baffled for each particular type of track. Probably the most interesting modification was the addition of a main cap girdle. Even so, main bearing saddle cracks were common. Stock 289 head gaskets were found to work reliably. |

|

Camshaft development was handed off to Jack Engle, ultimately settling on a relatively

short-lift long-duration camshaft. Rev kit springs were placed between the lifter valley

and the underside of the cylinder heads to extend the RPM range of the valve train.

Both 289 and 305 CID versions were dyno tested. On gasoline, the 289s developed as much as 506 hp @ 7800 rpm. The 305s pushed 520 hp. |

|