|

|

|

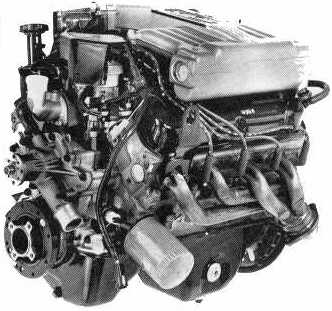

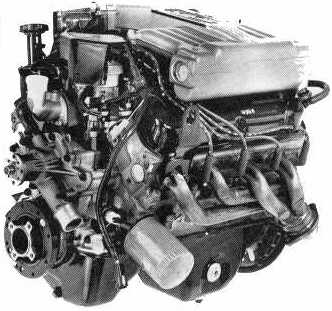

The Ford V-8 Engine Workshop 5.0 High Output |

|

|

|

In the early '80s the horsepower wars were back. Ford's entry in this race was the

new Fox chassis based Mustang powered by the newest member of the

Small Block family, the 5.0 High Output.

Fed initially by a 2V carburetor in 1982, followed by a Holley 4V carburetor, later by speed-density fuel injection, and ultimately by a mass airflow injection system, the 5.0 inched its way up from around 157 HP in 1982 to 225 HP in 1987. The 1985 and later engines feature roller tappet camshafts and factory short-tube headers; 1986 and later engines feature a ram-tuned intake system. The 1993 5.0 Cobra featured SVO GT-40 heads and intake manifold, better flowing exhaust, and a recalibrated EEC-IV computer. 235 HP. |

|

1982 -- 157 HP @ 4200

1983 -- 175 HP @ 4200

1984 -- 175 HP @ 4200

1985 -- 210 HP @ 4400

1986 -- 200 HP @ 4000

1987/88 -- 225 HP @ 4000

1989/92 -- 225 HP @ 4000

1993 H.O. -- 215 HP @ 4200

1993 Cobra -- 235 HP

|

|

Small block reciprocating assemblies have external balance. The crankshaft itself does not

carry enough counterweights to achieve zero balance. Extra counterweighting is cast into the

flywheel and harmonic balancer bring the entire assembly into neutral balance.

Early engines use 28.2 oz.-in. external balance, while 1982 and later engines use 50 oz.-in.

at the flywheel and 34 oz.-in. at the damper.

Automatic transmission flexplates have a welded-on weight plus a cutaway window on the opposite side. Rivets are used to fine-tune the balance. |

|

|

|

| Note the small counterweight on this 28.2 oz.-in. flywheel. This flywheel from a 1965/68 Mustang 289 has a 157 tooth ring gear. There are (6) 5/16"-18 pressure plate attaching bolts on an 11-3/8" circle. This holds a 10" clutch. Part # C3AZ-6375-J identified by casting # C6ZE-A and stamped engineering # C7ZE-B. | Note the larger counterweight on this 50 oz.-in. flywheel. Ford Motorsports part # M-6375-B302. This flywheel from a 5.0 High Output engine also has a 157 tooth ring gear. This holds a 10.5" clutch, accurately centered with alignment dowels and attached with metric bolts. |

|

Notice the missing section on the rim of this late model harmonic balancer. The part that isn't missing is the counterweight. |

| When converting from automatic to a manual transmission, be sure to use the correct flywheel bolts. Those specified for use with an automatic transmission flexplate and stiffener are not long enough. | |

|

|

| Current Ford Master Parts Catalogs specify part # D2AZ-6379-B bolts for both flexplates and flywheels. They are not long enough to properly clamp a manual transmission flywheel to the crankshaft. Don't trust 'em. | Obsolete but still available part # B8AZ-6379-A is the correct grip length. These bolts come with thread sealant pre-applied. |

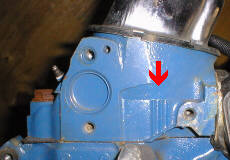

| The cast iron GT-40 cylinder heads may be identified by casting marks shown here. These GT-40 heads are casting # F3ZE-AA. Small block cylinder head casting numbers are found on the underside of the part, between the pushrod holes. | |

"GT" is cast in two places on the exhaust side of the head. |

Three vertical ribs are found on the front face of the right-hand head. |

| Modified: |